Spot Welder

Table of Contents

Introduction

In the past decade (the teens? can I call it that yet?) it has become increasingly apparent that batteries will be a major energy store for transport and home use. The problem with this is that for now batteries are expensive. The more "ready-to-use" a battery pack is, the less kWh you get per dollar. You also get pidgeon holed into whatever form-factor the manufacturer has decided, don't know the quality of the cells in your pack, and only get small set of voltages and current capacities to chose from. My (and many others) solution to this is to build my own battery packs.

There are a few spot welders available for this, you got the wall-powered chinese SUNKKO and the DIY variant the re-wround microwave oven transformer and options for "portable" welders there is the "Arduino Spot Welder" and the more profesional kWeld. The Arduino Spot welder and the kWeld seemed simple enough so I figured that I'd try my hand at making something similar.

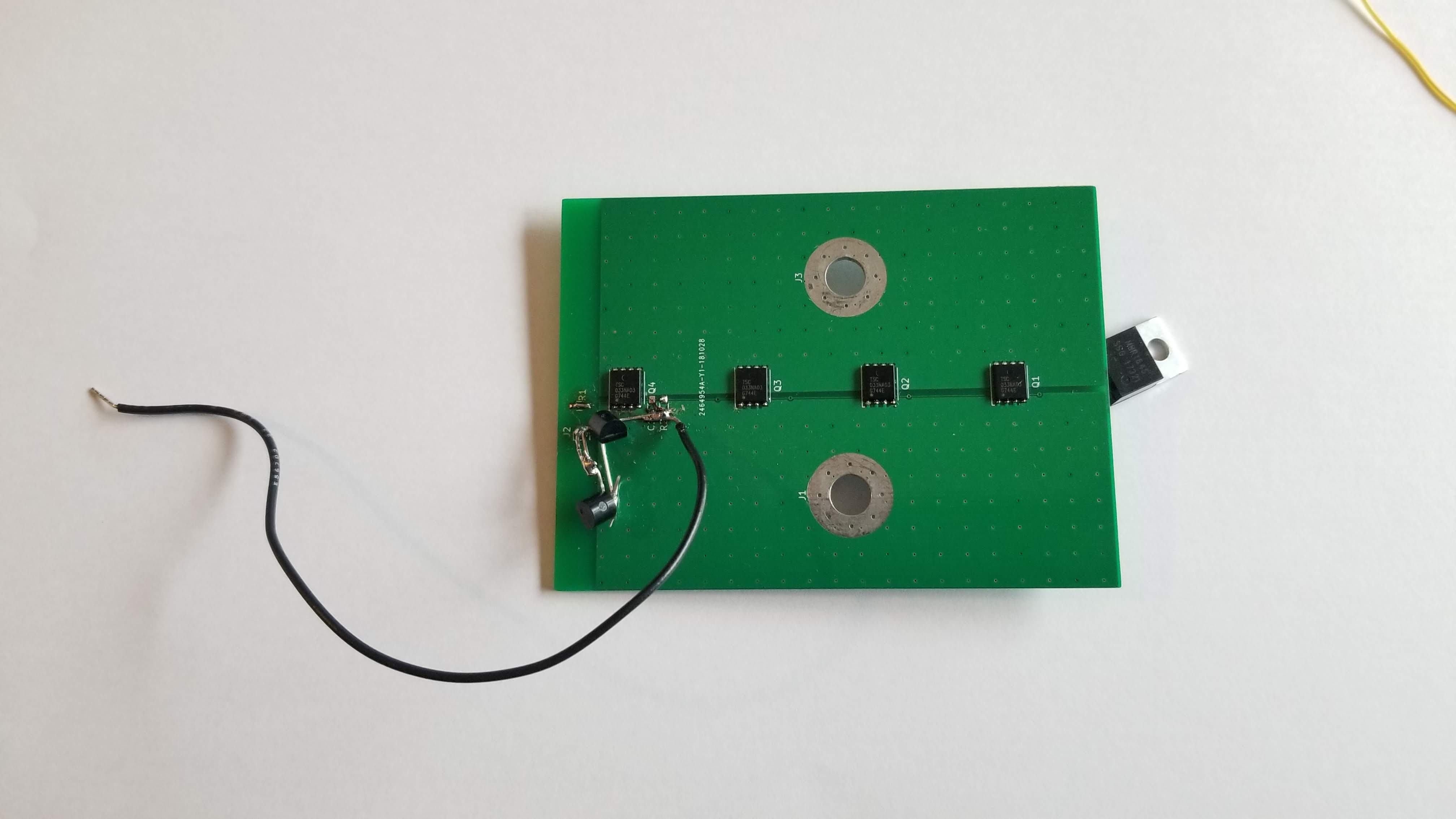

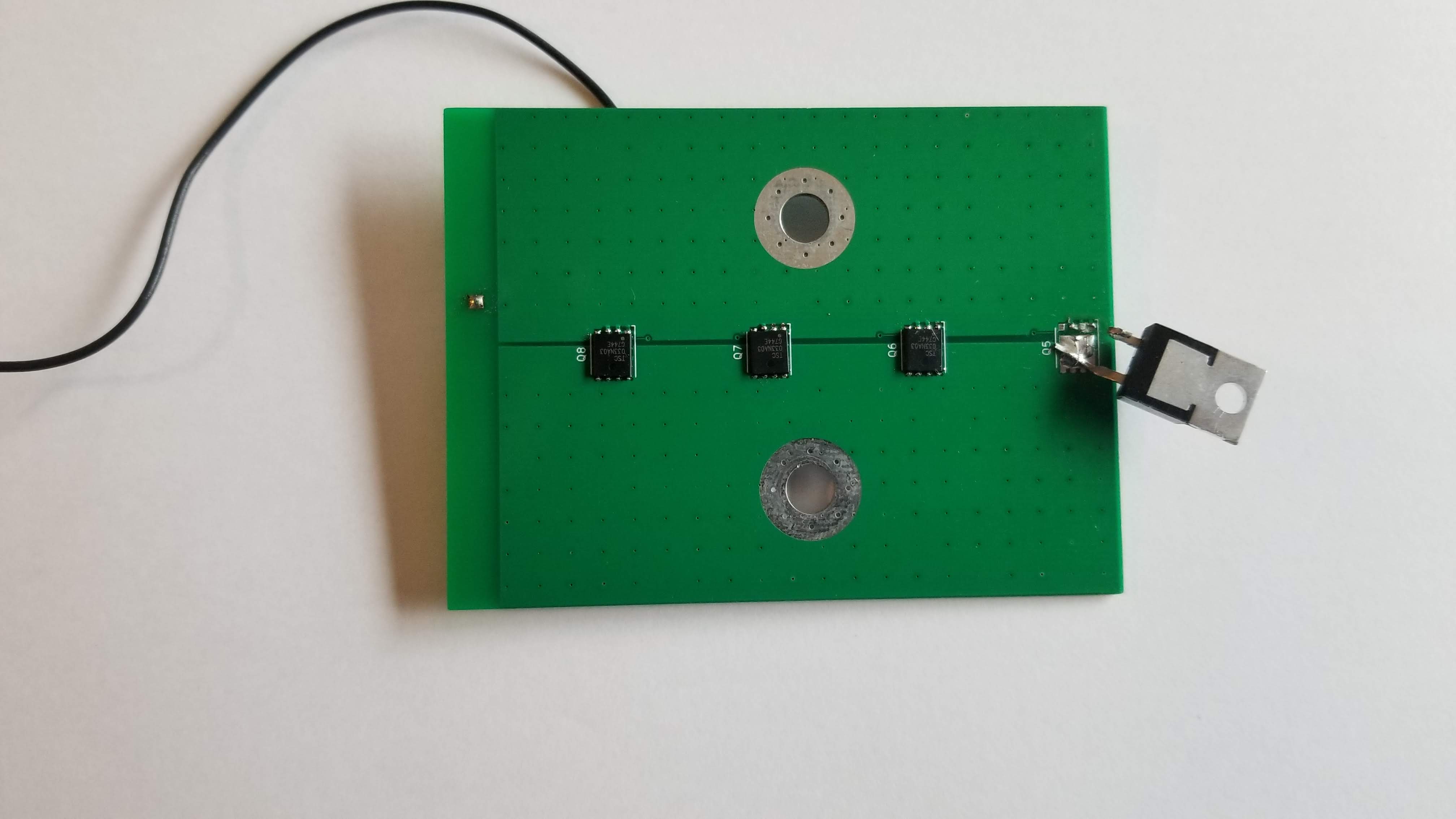

Version 0

This is version 0 because I never really expected it to work out all that well. The impetus for this version was trying out JLC PCBs $2* fab process. I quickly whipped something up in KiCad that matched the promo's parameters to try out the service and blow up some FETs.

*Not really $2, I ended up paying $18(!) for shipping. When fabbing PCB's outside of the $2 promo my shipping costs were much more reasonable, ~$10 or less.

Much to my dismay, I didn't blow up any FETs (During my testing I did get a few to fail short but nothing catastrophic :( ). In my infinite wisdom I decided to put thermal reliefs to help when soldering down the FETs to the large plane but failed to realize those same features make great fuses!

After realizing this mistake I went back to the drawing board to design something with a bit more resiliance and thought into the design.

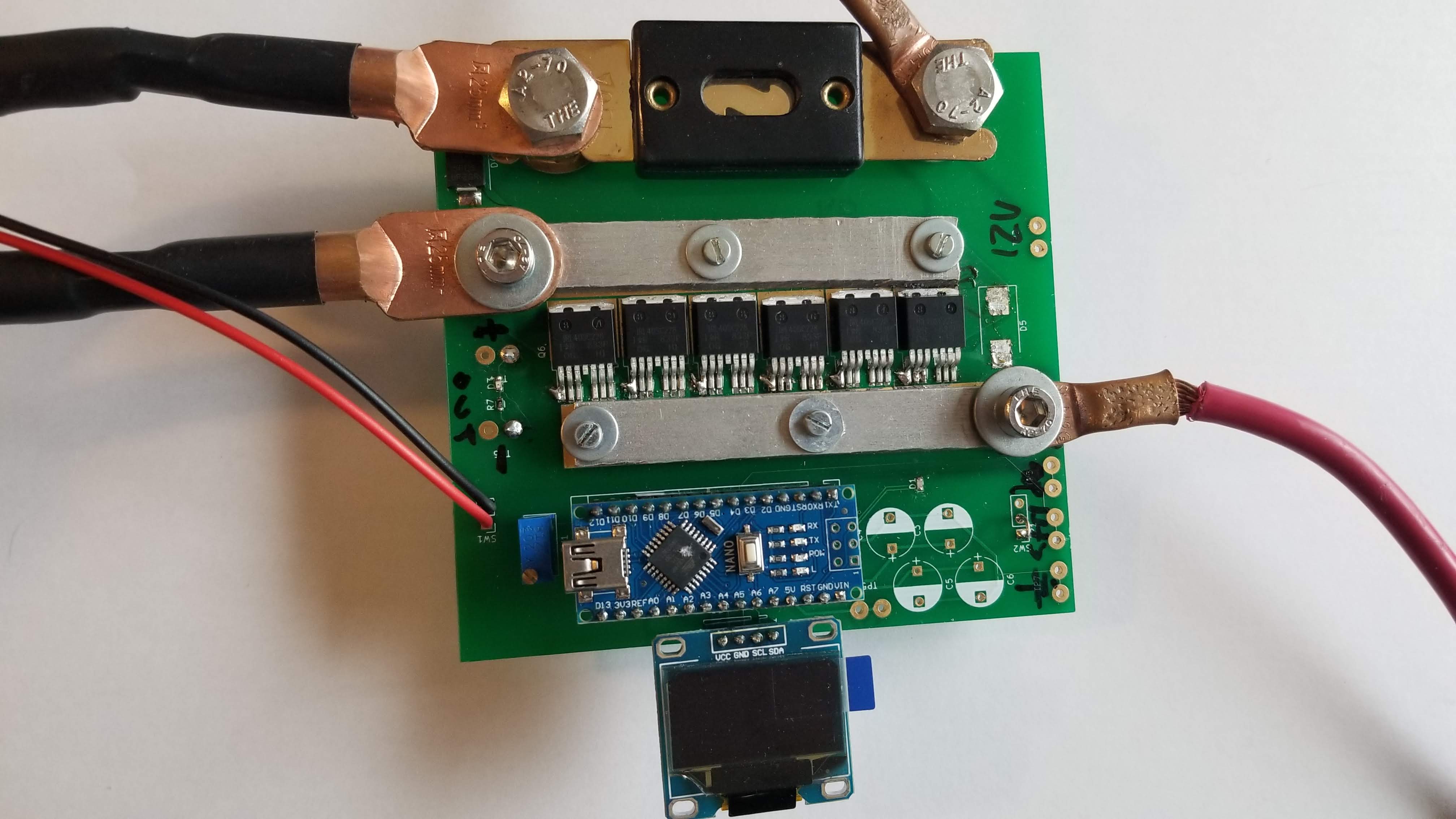

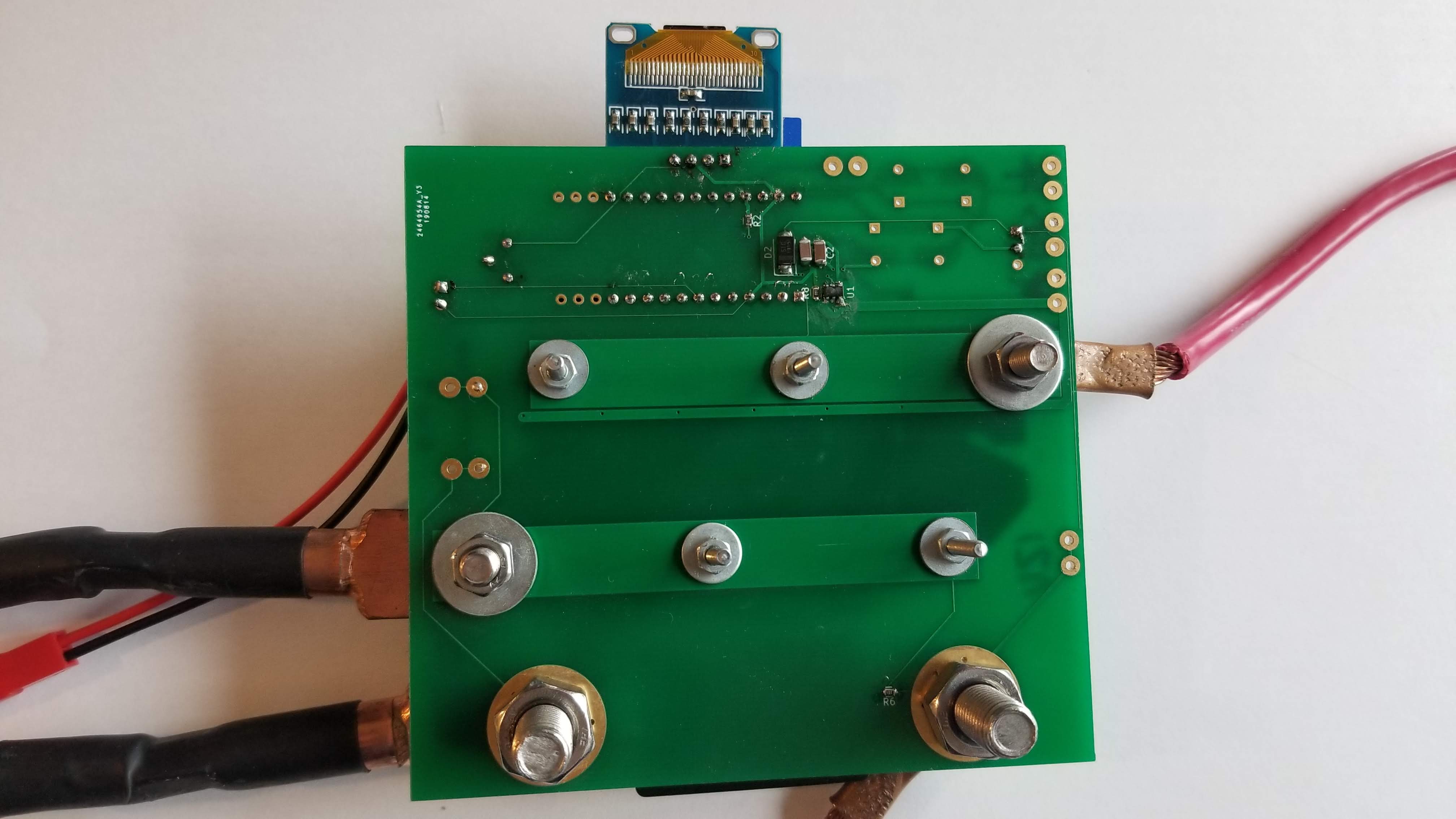

Version 1.0

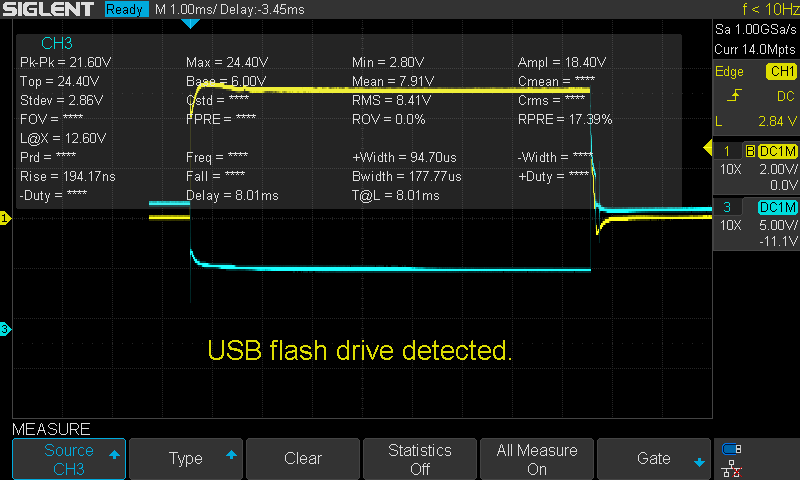

V1.0 is quite an improvement over V0, board reliability went from 1 weld to over 200 welds a 20000% increase, wow! In reality you can see the design has been inspired by both the portable welders I mentioned in the introduction. I think the major improvements to reliabilty is due to the package choice for the MOSFETs, the SON-8 package (used in V0) has a much lower current capacity compared to the fatty D2PAKs. The aluminum bus bars aren't even strictly necessary, I was able to complete a few welds without them, the input and output traces would raise a few degrees C after each pulse though.

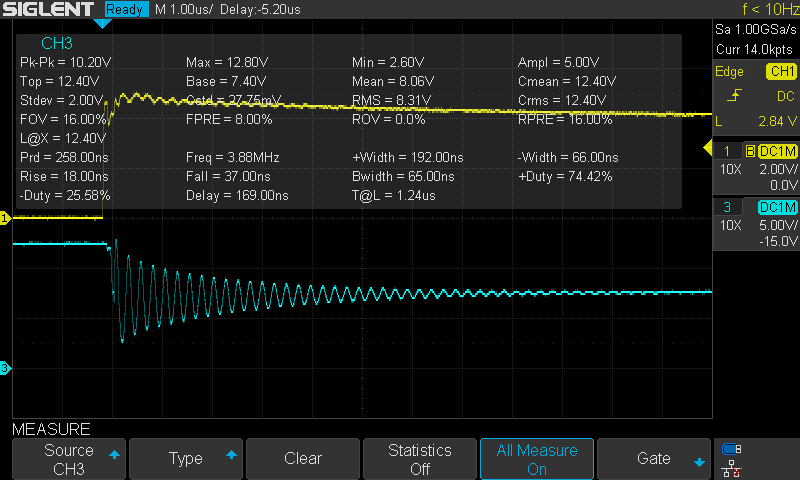

The ringing shown above I believe is the reason I need to make a V1.1. While I designed in gate resistors for each MOSFET, when building this board I realized I didn't have any low resistance 0402 resistors, I only had 0603s. So in the interest of keeping things moving for testing I placed a nice glob of solder to short out the gate resistor pads (can be seen in the front V1.0 picture, next to pin 1 of the D2PAKs). This ringing probably lead to an repetitive avalanche failure from the MOSFETs due to them switching large currents very fast. Before moving on to V1.1 with the gate reistors I want to figure out how many FETs blew.

Version 1.1

Version 1.1 is effectively the same as V1.0. It will use the same board as V1.0 incorporating the gate resistors to slow the turn on just a tiny bit to prevent any ringing at the gate.

Future

Ideally in the future I would like to get this project to a point where I have a reliable, compact and portable spot welding station. Currrently the old car battery doesn't facilitate the portability of the device, the kWeld can use high discharge rated li-poly batteries. I think it would be cool to use the same 18650 li-ions to power the welder, though I haven't redearched what that would end up looking like.